Success stories

OSSTEC

Next-gen knee replacements to help more people stay active

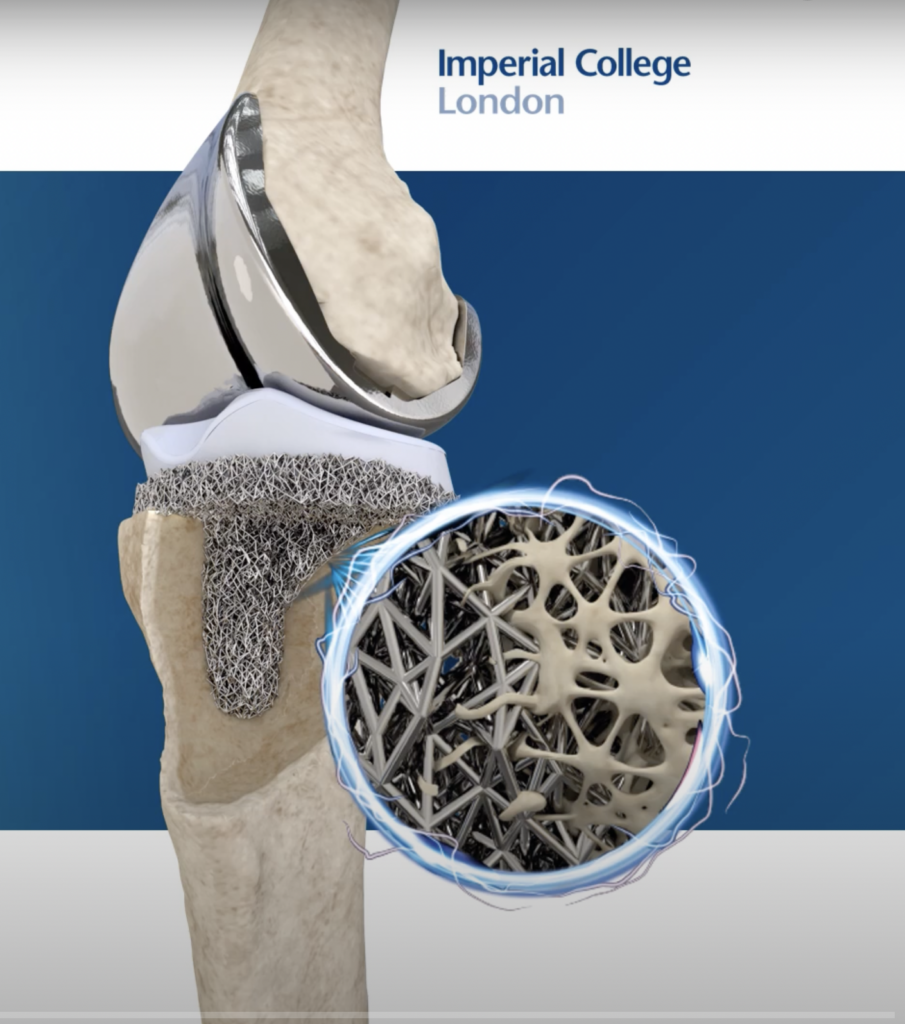

A bioengineering startup from Imperial College London is developing 3D-printed orthopaedic implants that mimic the properties of real bone and even stimulate the growth of healthy tissue in people with osteoarthritis.

With around 1.3 million knee replacements performed globally every year, OSSTEC’s proprietary implants should lead to better outcomes and fewer complications for patients.

The company was founded in May 2021 by Dr Maxwell Munford after he took part in the MedTech SuperConnector (MTSC) and has now attracted around £800,000 in public funding. In addition, Max has recently been appointed to the highly prestigious position of Enterprise Fellow at the Royal Academy of Engineering.

Long-standing ambition

After completing an MEng in Mechanical Engineering at Imperial, Max interned at a couple of medical device companies before embarking on a PhD in Additive Manufacturing for Medical Engineering (also at Imperial).

Max had long harboured ambitions to create a venture himself and when his PhD started yielding promising results he saw an opportunity and successfully applied to the MTSC.

“I really thought a lot of the MTSC as a program and always recommend it and flag it to new PhD students coming through who show some interest in the venture route as a way to really help you get your ideas off the ground.”

The need for better implants

Max explains that the knee joint is comprised of the upper end of the shin bone (tibia) and lower end of the thigh bone (femur), which are covered by smooth cartilage and so normally glide over each quite easily. In people with osteoarthritis the cartilage becomes damaged or worn away, with bone spurs sometimes appearing, causing considerable pain and stiffness. One option is for a total or partial knee replacement, where a surgeon will insert generally solid metal in place of damaged bone. This relieves pain and can restore a degree of function for people.

However, over time, loss of bone quality can occur, leading expensive revision surgeries and complications.

OSSTEC’s solution is the development of next generation implants that are 3D-printed in a lattice structure using a titanium that behaves like bone, as Max explains.

“Bone is this wonderful porous material, which is dynamic and it grows more when you load it more and it grows less when you load it less. This is the reason why tennis players for example will have stronger bone in their dominant arm – because it is loaded more. Conversely with existing implants, you replace bone with an alien material, solid metal, and you shield it from being loaded in the way it normally would be. When this happens you stop the bone from being able to grow in a healthy way. What we do is mimic the bone with the implant, so we stimulate it in the same way and encourage it to re-grow long-term.”

Route to the clinic

OSSTEC has carried out vital pre-clinical studies in sheep and human cadavers, to gain an understanding of how their implants are performing and the team is currently pursuing regulatory approval.

The company has won around £800,000 in public funding to date and is raising private seed investment.

Max says what he is most proud of in his journey to date is assembling a strong team – including his co-founders Professor Jonathan Jeffers and Mr Alex Liddle (both Imperial), new employees, a panel of expert advisors and a Chair.

Along the way Max has had the chance to learn from some amazing mentors who have been on the venture journey themselves and says that having input from trusted mentors is key when taking technology from the lab to the operating room.

“I grew up in an environment where I was very aware of what it meant to run a business, so my journey and my passion for going down this route started some time ago. But the MTSC was basically the first time I got any kind of formalized training on what it takes and how to start moving the technology forward to get this thing off the ground. It helped me answer questions about where we should go from here and what the first steps would be.”

Dr Max Munford, Founder of OSSTEC